Impact bar is an important cushion part.

Slow down the material on the conveyor belt and the impact damage, avoid sharp objects for tape tearing and scratches.

Used in belt conveyor material guiding groove, blanking point below the belt.

Outstanding capability to absorbing impact and low friction coefficient.

UHMW Rubber Impact Bar for Conveyor Belting Protect

Flame retardant and antistatic Impact bar can meet the requirements of special environment such as coal mine underground. This type of product produced by our company meets the industry standards and has obtained the national coal mine safety product license.

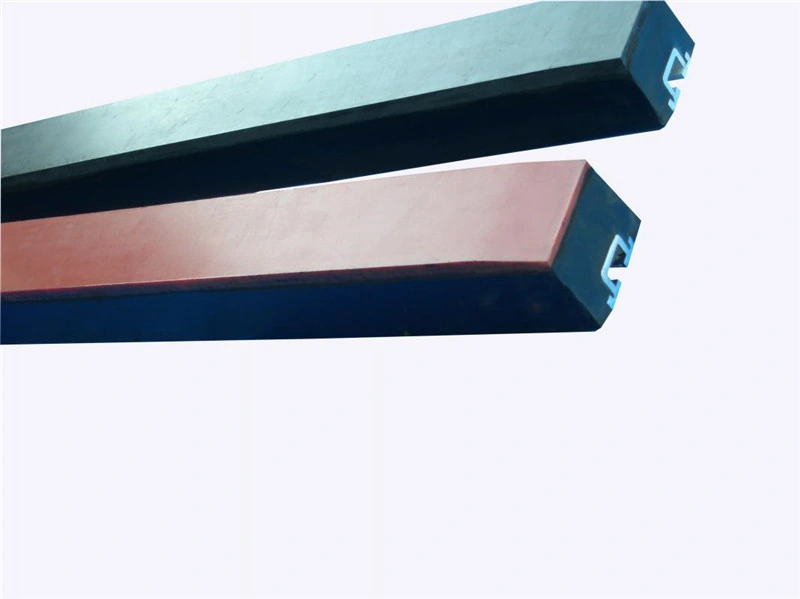

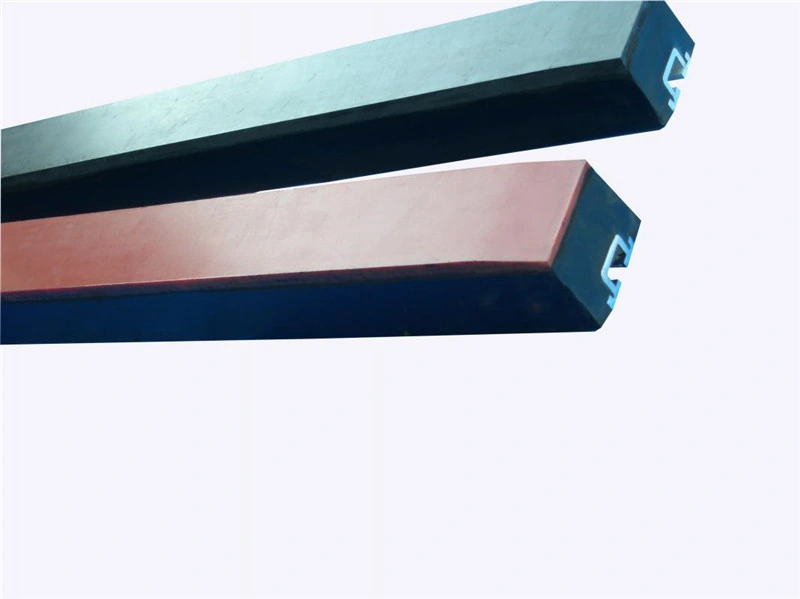

The product structure

Impact Bars is a fusion of three different layers:

-UHMWPE Cap

- Rubber

-Metal Slot

All parts of the impact bar are closely jointed by hot vulcanization

Product specification

Features and advantages

1. High-quality impact-resistant rubber provides excellent cushioning and shock absorption, while rubber has flame retardant, antistatic properties, can be used to ensure the safety of special places

2. The UHMW-PE also has flame retardant and antistatic properties.The high quality surface has outstanding sliding properties, will reduce effectively the wear on the conveyor belt.

3.T-slot" extruded metal construction allows fixing of our impact bars along the entire length of the impact bar which allows for easier installation and disassembly.

4. Manufactured by hot vulcanization which leads in an efficient and reliable jointing between the parts.

Contact:

Slow down the material on the conveyor belt and the impact damage, avoid sharp objects for tape tearing and scratches.

Used in belt conveyor material guiding groove, blanking point below the belt.

Outstanding capability to absorbing impact and low friction coefficient.

UHMW Rubber Impact Bar for Conveyor Belting Protect

Flame retardant and antistatic Impact bar can meet the requirements of special environment such as coal mine underground. This type of product produced by our company meets the industry standards and has obtained the national coal mine safety product license.

The product structure

Impact Bars is a fusion of three different layers:

-UHMWPE Cap

- Rubber

-Metal Slot

All parts of the impact bar are closely jointed by hot vulcanization

Product specification

| Length (mm) | 500 600 800 1000 1220 1400 1524 1600 1800 | |||

| Width (mm) | 100 250 | |||

| Height (mm) | 50 55 60 70 75 80 90 100 | |||

| Thickness of wear resistant layer (mm) | 8 10 12 13 15 20 25 30 40 | |||

| Metal slot |

| |||

| Standard Screw | M12 M16 M18 M20 1 Set of screws includes bolts, gromment and nut | |||

| Type | Normal | High Elastic | Flame Retardant | Special customization |

Features and advantages

1. High-quality impact-resistant rubber provides excellent cushioning and shock absorption, while rubber has flame retardant, antistatic properties, can be used to ensure the safety of special places

2. The UHMW-PE also has flame retardant and antistatic properties.The high quality surface has outstanding sliding properties, will reduce effectively the wear on the conveyor belt.

3.T-slot" extruded metal construction allows fixing of our impact bars along the entire length of the impact bar which allows for easier installation and disassembly.

4. Manufactured by hot vulcanization which leads in an efficient and reliable jointing between the parts.

Contact: