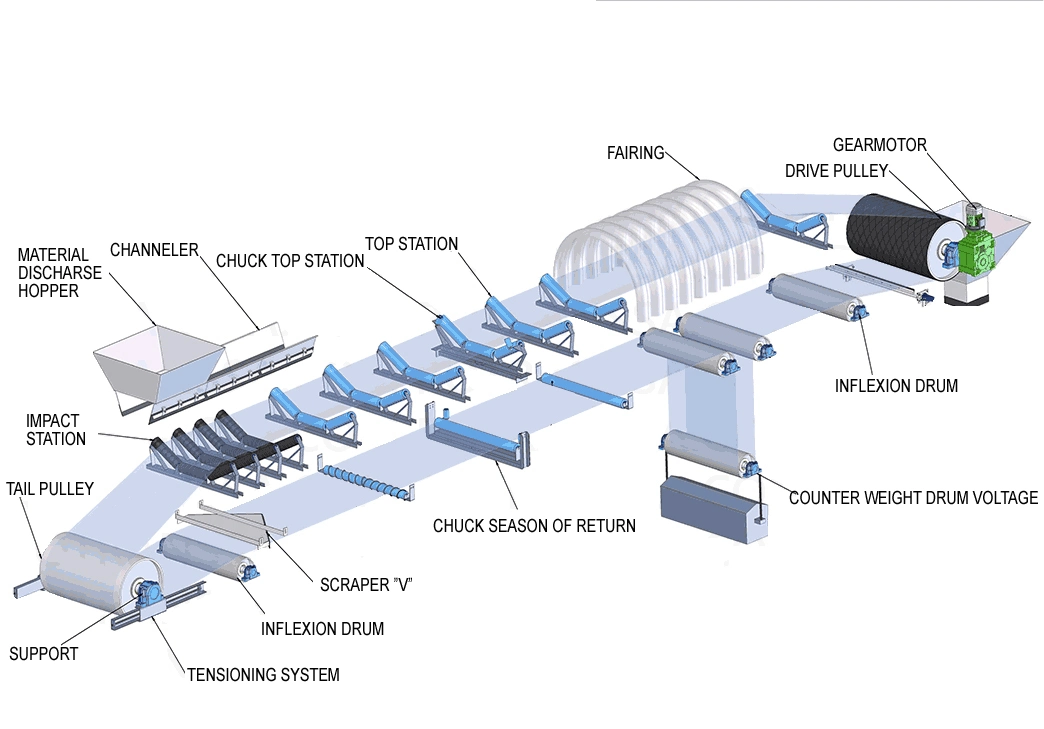

Stone Crushing Plant Belt Conveyor for aggregates transportation

Features:

1.Large conveying capacity and longer conveying distance, up to 20km or longer

2.can conveyor various kinds of bulk material and itemized goods with bulk density of 0.5~2.5t/m³

3.can adopt combined conveying mode of convex curved segment,concave curved segment or straightline segment.

4.according to different transportation request, it can be single used or multiple combined using, also can be used together with other equipments to organize a horizontal or declining conveying system.

5. It can be used between -25ºC~+60ºC working environment, temperature of conveying material under 80ºC with high adaptability.

Principle:

Belt conveyor is composed by frame, belt, roller, tensioning device, transmission device, etc. The frame adopts high quality steel for connection, a certain angle inclined plane is formed because of the different heights of front and rear legs. The machine frame is fixed by belt roller and carrying roller which are used to drive and support the conveying belt. There are two driving ways: geared motor driving and electric roller driving.

Technical parameters

| Belt width (mm) | Belt length(m)/Power(kw) | Conveying speed (m/s) | Capacity (t/h) | ||

| (L/kW) | (L/kW) | (L/kW) | |||

| B400 | ≤12/1.5 | 12-20/2.2-4 | 20-25/3.5-7.5 | 1.3-1.6 | 40-80 |

| B500 | ≤12/3 | 12-20/4-5.5 | 20-30/5.5-7.5 | 1.3-1.6 | 80-190 |

| B650 | ≤12/4 | 12-20/5.5 | 20-30/7.5-11 | 1.3-1.6 | 130-320 |

| B800 | ≤6/4 | 6-15/5.5 | 15-30/7.5-15 | 1.3-1.6 | 280-550 |

| B1000 | ≤10/5.5 | 10-20/7.5-11 | 20-40/11-12 | 1.3-2 | 440-850 |

| B1200 | ≤10/7.5 | 10-20/11 | 20-40/15-30 | 1.3-2 | 660-120 |

Note: All the above information is subject to our final confirmation.